Bekamak product development studies started with the establishment of the design and product development department in the 2000s. First of all, ideas from white-collar and blue-collar employees form the basis of improvement.

In this context, the company aims to develop innovative products with high added value in order to increase its competitive power in the world, to consolidate its leading position in the export of sawing machines, and to increase its share in exports. In line with this goal, Bekamak R&D center was approved by the Ministry of Industry and Technology on the 06.07.2018 and received the title of 943. R&D centers in order to carry out projects in coordination with universities and research centers, to create a culture of innovation, and to lead in learning and developing new technologies. .

In Bekamak R&D Center, studies are carried out in accordance with the Law No. 5746 on Supporting Research, Development and Design Activities. Since 2018, approximately 5% of the company's turnover is devoted to R&D activities.

| Application | File Number | Title |

|---|---|---|

| Patent | 2025/022754 | Hybrid Dual-Parameter Directional Curvature Sensor Incorporating V-Grooved Polymer Optical Fiber and a Spiral-Wound FBG |

| Design | 2025 006917 | High-Speed Sawing Machine |

| Patent | 2025/017148 | A Feeding Verification System Supported by a Contact Roller and Encoder |

| Patent | 2025/006604 | A Circular Saw Machine Equipped with an Automatic Cooling System Sensitive to Cutting Temperature and a Related Method |

| Patent | 2024/021293 | A Saw Machine Enabling High-Speed Cutting of Materials with Rectangular Cross-Sections |

| Patent | 2024/008527 | Quality Defect Detection and Optimization System for Sawing Machines |

| Design | 2023 013361 | Band Saw Machine |

| Design | 2022 013967 | Metal Cutting Band Saw Machines |

| Patent | 2022/008496 | Cutting Control System |

| Patent | 2021/019161 | A System for Detecting the Geometric Structure and Dimensions of the Workpiece in Sawing Machines |

| Patent | 2021/017061 | An Automatic Saw Changing System and Method |

| Patent | 2020/12892 | Cutting Tool Data System for a Band Saw Machine Used in Metal Cutting |

| Patent | 2020/06645 | A Configuration Providing Oscillation Capability to the Cutting Tool of a Band Saw Machine |

| Patent | 2019/13458 | A Servo-Controlled Automatic Circular Saw Machine Providing Low Scrap Rate and High Efficiency |

| Patent | 2019/03894 | A Horizontal Band Saw Machine Capable of Cutting at Variable Angles |

| Design | 2019/03473 | Metal Cutting Machine |

| Utility Model | 2018/01748 | An Innovation in a Horizontal Band Saw Machine Having Angular Cutting Capability |

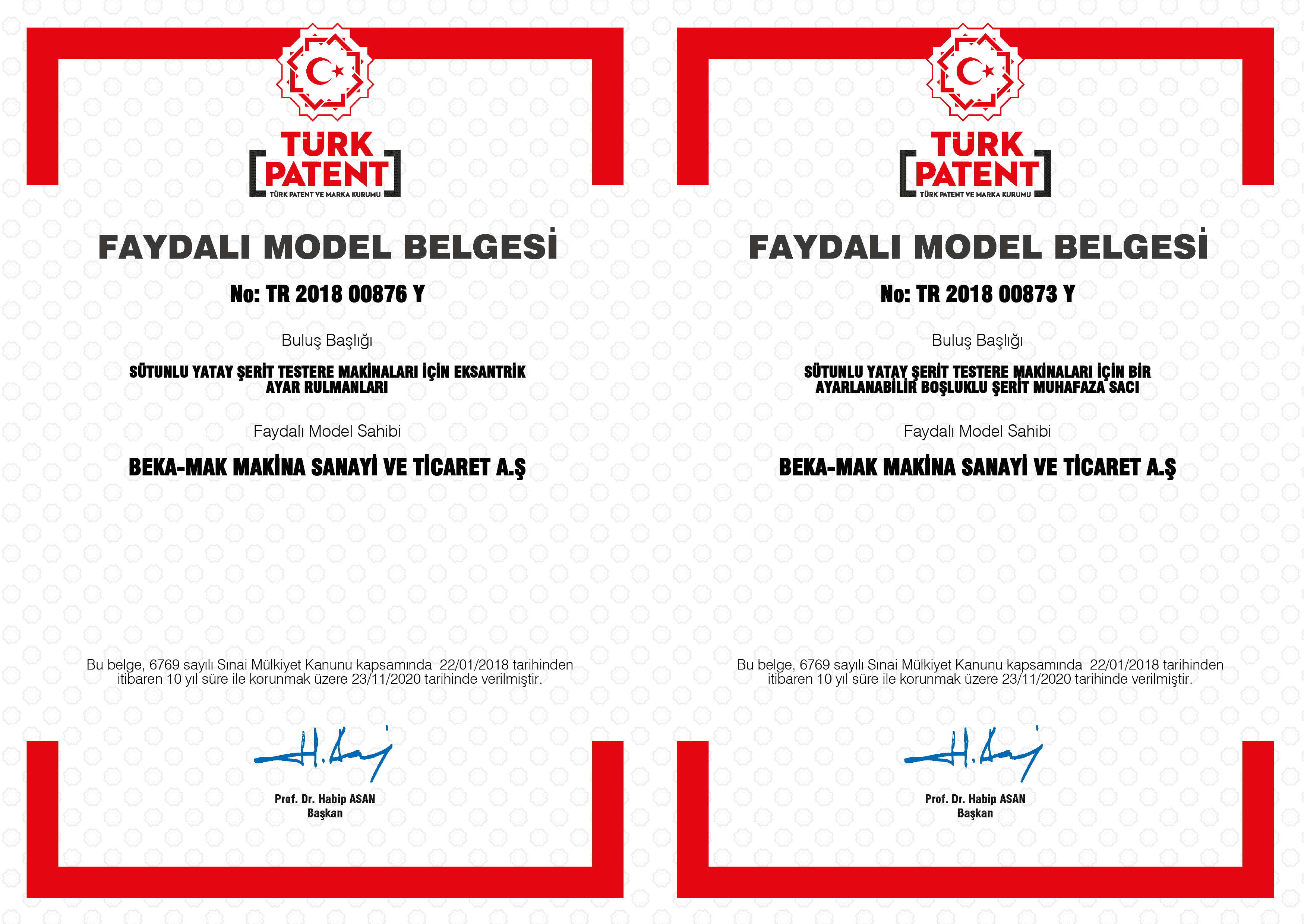

| Utility Model | 2018/00873 | An Adjustable-Clearance Band Guard Plate for Column-Type Horizontal Band Saw Machines |

| Utility Model | 2018/00876 | Eccentric Adjustment Rollers for Column-Type Horizontal Band Saw Machines |

| Utility Model | 2017/23228 | An Angle Locking Mechanism for Horizontal Band Saw Machines |

| Utility Model | 2017/21972 | An Encoder-Based Angle Indicator for Horizontal Band Saw Machines |

| Design | 2017/08626 | Metal Cutting Machine |

| Date | Title | Conference / Journal |

|---|---|---|

| 30.10 - 02.11.2025 | Investigation of the Effects of Cooling Conditions on Energy Consumption and Surface Roughness Sawing of AISI 1045 Steel | 13th UTIS International Congress on Machining |

| 30.10 - 02.11.2025 | Artificial Intelligence–Based Parameter Optimization and Predictive Maintenance Application in Sawing Machines | 13th UTIS International Congress on Machining |

| 10/20/25 | Prediction of Cutting Parameters in Band Sawing Using a Gradient Boosting-Based Machine Learning Approach | MDPI-Machines |

| 10/3/25 | Characterization of Saw-Cut AA7075 Surfaces in Terms of Surface Roughness | Journal of Machine Design and Manufacturing |

| 5/27/25 | Investigation of the Effects of Cutting Forces Generated in Band Saw Machines on Workpiece Surface Roughness and Cutting Perpendicularity | Journal of Machine Design and Manufacturing |

| 11-13.07.2025 | Lightgbm-Based Data Driven Modeling of Band Sawing Cutting Parameters for High-Hardness Tool Steels | 12th International European Conference on Interdisciplinary Scientific Research |

| 16-18.03.2025 | Experimental Investigation of the Effect of Cutting Tool and Cutting Parameters on Energy Consumption in Sawing Process | 8th International Ankara Multidisciplinary Studies Congress |

| 1-3.11.2024 | The Effect of Cutting Parameters On R-Effect Update and Cutting Times in Saw Machines | 12th UTIS International Congress on Machining |

| 14-17.08.2024 | Investigation of the Effect of Cutting Force Generated in Sawing Machines on Workpiece Surface Roughness and Cutting Perpendicularity | 20th International Conference on Machine Design and Production |

| 2-3.12.2023 | Investigation of the Effects of Cutting Parameters on the Workpiece in Band Saw Machines | 11th International Congress on Engineering Sciences and Multidisciplinary Approaches |

| 7-8.09.2023 | Optimization of Cutting Parameters By Measuring Cutting Force in Sawing Machines | MD International Conference on Machine Design |

| 31.08-03.09.2022 | Investigation of the Effects of Vibrations Generated on the Cutting Tool on the Workpiece in Circular Saw Machines | 19th International Conference on Machine Design and Production |

| 23-31.07.2022 | Experimental Determination of Cutting Force in Band Saw Machines | 4th International Ankara Multidisciplinary Studies Congress |

| 10-13.05.2022 | Experimental Investigation of the Cutting Process on Band Saw Machines | 1ST INTERNATIONAL CONFERENCE ON ENGINEERING AND APPLIED NATURAL SCIENCES |

| 08-11.12.2021 | A Predictive Maintenance Application for Band Saw Machines | VI INTERNATIONAL SCIENTIFIC CONFERENCE “Industry 4.0” |

| 24-25.12.2021 | Experimental Approach for Determining Optimum Cutting Parameters on Band Saw Machines | ISPEC 12 th INTERNATIONAL CONFERENCE ON ENGINEERING & NATURAL SCIENCES |

| 13-15.11.2020 | Modeling and Control of Twin Parallel Axis Linear Servo Mechanisms for Gantry Type Heavy Duty Saw Machines | ISPEC 9 th INTERNATIONAL CONFERENCE ON ENGINEERING & NATURAL SCIENCES |

| 13-15.11.2020 | The Effect of Cutting Speed on Cutting Tool Temperature in Band Saw Machines | ISPEC 9 th INTERNATIONAL CONFERENCE ON ENGINEERING & NATURAL SCIENCES |

| 11-14.12.2019 | Determination of Industry 4.0 Compliance Criteria for Band Saw Machines | IV INTERNATIONAL SCIENTIFIC CONFERENCE “Industry 4.0” |

19th International Machine Design and Manufacturing Congress

August 31 - September 3, 2022

We participated in the 19th INTERNATIONAL MACHINE DESIGN AND MANUFACTURING CONGRESS held in Nevşehir, hosted by Kapadokya University, with a paper titled "Investigation of the Effect of Vibration on the Cutting Tool on the Workpiece in Circular Saw Benches".